A Visit To An Amish Noodle Business (16 Photos)

You may have seen Amish-made noodles for sale in shops or even tried some yourself.

Today Don Burke takes us to an Amish noodle-making business, to share a behind-the-scenes look at how these noodles get made.

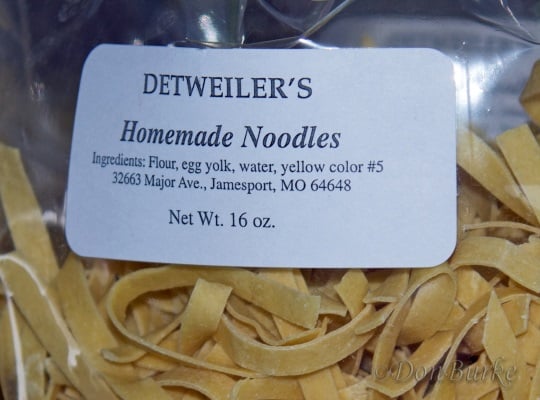

While in Jamesport, MO, a few years ago I had the opportunity to visit the facilities where a local Amish family made their Detweiler’s Homemade Noodles.

These noodles were a staple in the local stores and other venues, and were enjoyed by locals and tourists alike.

And by “facilities” I mean a quite-small single-room building, located right next to the family home.

This was in the truest sense a mom-and-pop enterprise, although the school-aged among the family’s half-a-dozen little ones did help some as they were able to.

Noodles were a side-line family business as the father’s primary job was operating his wood-finishing shop and occasionally helping as a seasonal part-time carpenter.

The time demands of noodle-making fluctuated, sometimes taking a half-day or so out of their week, and at other times taking two or three days as they prepared for the additional traffic of a community festival and other business peaks.

The various pieces of powered equipment used in the noodle-making process were run on a shaft-and-belt system, which was powered by a small gasoline engine outside of the building.

The Noodle-Making Process

The ingredients were mixed by a large commercial mixer, and the dough was portioned off and hand-rolled into rough irregular rolls.

The dough was then run through the first of a two-stage flattening process.

The semi-flattened dough was laid out on a table, and cut into smaller sections,

…then taken back to the roller…

and run through the second stage of flattening.

After flattening, the noodle strips were placed individually on screen drying shelves,

…and the full rack of screens was set aside to air dry.

Forced-air fans aided in the drying if weather conditions required.

Once mostly-dry, the still-flexible noodles are gathered and cut. This cutting will largely determine the length of the final product.

Next, the width of the final noodle was set as the flats were run through either the wider cutter or the narrower cutter.

From here the cut noodles are set aside to finish drying, packaged into clear bags, and were then ready to sell.

The Detweiler have since sold the business to another Amish family in the Jamesport community. As far as I know this other family continues the business today.

Thanks go out to Don for showing us how these yummy noodles get made. Find more of his Amish photos and others, on Flickr.

Fascinating – I always like to learn how things are made. Thanks, Don and Erik.

Yes the business has been sold and is still going strong! These noodles are a fast seller and are delicious!

yellow #5 ?

You use yellow #5? I can’t believe that the Amish use artificial colors made from petroleum in their all-natural food products. Please tell me it’s not true. I don’t care what the FDA says.

Egg noodles

Thanks for the photos and story on how they make their noodles. It was really neat.

Noodles

Thanks Erik for once again giving me the opportunity to share an Amish experience here. And Marie is right — they are quite tasty!

Thanks for this post. I’ve seen lots of Amish noodles for sale — in big stores like E & S Bulk Foods in Shipshewana, as well as in small produce stands on Amish farms. I always wondered how they were made and didn’t realize it took so long and is so much work. I wonder how this method of making noodles compares to the way they are made in large commercial noodle factories.

Noodles.

We love your noodles. They are hard to find here. I am going on a tour group in September to Lancaster Pa, and I will buy some more there and other Amish food, like Shoo-fly pie, my husband favorite. I enjoyed the photos of the noodle factory. I was wondering, can we buy the very wide noodles to make Lasagna? Thank you so very much. My daughter and her family loves your noodles too. Another question, where can I buy Amish peanut butter, that used to come in a jar, not a plastic bottle.

Joan, I wrote the article, but I’m afraid that I am not in any way connected to the people that make the noodles. In fact, we live on opposites sides of the state, and I don’t even know the people that operate the business now. Back when I took the pictures I never the business do the larger noodles you asked about, but I don’t know what they do now. And sorry, but I don’t know the answer to your peanut butter question either.